CAMERA IMAGE QUALITY TUNING

Camera image quality is an essential part of the performance of any device containing a camera. The optoelectronics experts at Sigma Connectivity can help you with all aspects of this, from selecting a camera sensor and module suitable for the use cases to tuning and calibration of the image signal processing (ISP) algorithms in the chipset, and all the way to subsequent testing and verification of prototypes. The items to evaluate cover things like exposure, color rendering, white point balance, contrast, distortion, MTF, uniformity, sharpness, noise, etc., all done in our state-of-the-art camera labs

At Sigma Connectivity we have a wide range of labs needed for camera image quality tuning and prototype testing and evaluation, as well as the skilled experts to operate them.

The labs also contain equipment used for the other types of optical technologies the team works with, such as different types of displays and LEDs and optical sensors ranging from simple light sensors to 3D mapping systems. View our labs here.

Mattias Eriksson

Engineering Manager, Optoelectronics Design & Lab

Cameras have become much more accessible for many products during the past few years. Image sensor performance has improved, and image signal processing chipset performance for managing the camera and images has increased at reasonable cost and power consumption, allowing for high-quality accurate images on the device. Even computer vision and machine learning with edge computing based on images have also become more accessible.

The driving force behind this progress can be attributed to the strong development in the smartphone market we have witnessed since its inception, which can now be utilized in any type of product. Sigma Connectivity is optimally suited to handle this as our heritage is from the smartphone market from Sony Mobile/Sony Ericsson, and we are now able to apply those skill sets to any market vertical.

HOW WE WORK WITH CAMERA IMAGE QUALITY

-

Image quality contains several aspects, and it is not the same thing for all applications. A general-purpose camera product where a human will be the receiver of the image has certain requirements, and items like color rendering, white point balance, uniformity, and noise will be important. If the receiver is a computer vision system, other items like sharpness and contrast may be of higher importance. And then there are countless special cases where other aspects are more important, for example, if the camera is paired with its own specialized infrared light source for night vision, or in a medical application where some selected aspects of the image quality contain all the information needed for diagnosis.

-

The exact procedure is determined by the SW support functions from the ISP (image signal processing) chipset provider, like for example Chromatix from Qualcomm, which the Sigma team has extensive experience with. The steps needed also vary depending on the exact product use cases, ranging from basic objective tuning in well-known lab environments (where numerical values can be obtained to quantify the image quality), to subjective tuning in real-life use-case specific scenes where the image needs to be evaluated by an experienced camera expert engineer using calibrated reference equipment. Often the subjective testing includes a reference device used to benchmark against. But the general steps are the same for all ISPs, from major chipset providers like Qualcomm/Ambarella/MediaTek/NXP, to camera sensors with its own built-in ISP.

-

It is important that a project clearly defines all aspects of the desired solution where the camera is to be used. The optoelectronics team members are well experienced to discuss this and help you as a customer specify all use cases. We can also from our broad experience with multiple products help you understand what is possible with different types of state-of-the-art camera technologies.

-

What camera is most suited to use for your specific use cases? Our team works as camera experts in every project and is in continuous contact with multiple suppliers and we evaluate camera technology daily. This means that we know what camera sensor type would be suitable for You and its strengths and weaknesses. It is also very important to combine a camera sensor with a suitable host chipset to make a good match for optimal performance.

-

A camera sensor must be paired with a lens suitable for the use cases and the whole module must be developed and manufactured to fit the product. The camera team will help you find a suitable module supplier, specify the module to be made, and evaluate the integration of the camera sensor in the module to find the best performance at the most competitive price. We can also test and benchmark different off-the-shelf modules for the best performance.

-

How do we ensure that the product is designed and developed to give the best camera performance? The camera team is well experienced in collaborating with all other engineering competencies needed to fulfill the entire product requirements. This would cover all aspects of industrial design, electronics design, mechanical CAD, and SW. We can also support anything from optical simulations of flash LED illumination of the scene, to support the development of custom image processing algorithms if needed.

-

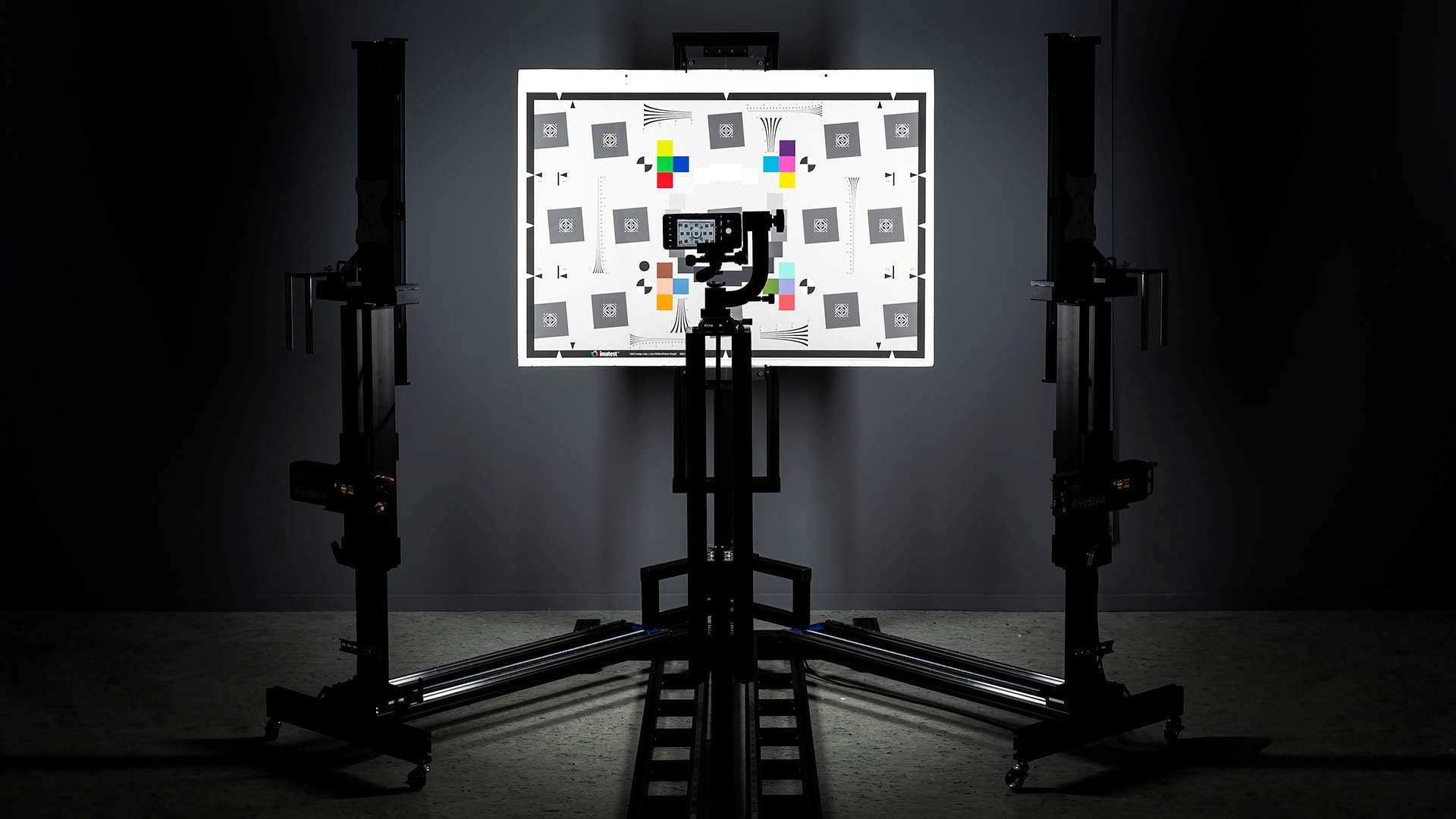

The camera labs at Sigma Connectivity are used for several steps in the development process. Besides the image quality tuning, the same labs are also used to verify that the prototype is built according to design and expectations. We have many types of specialized equipment to evaluate all aspects of the camera system performance, and we can even design custom-made tests for a specific application.

IMAGE QUALITY ASPECTS AND METHODS

-

Sharpness & MTF sharpness is an objective factor that determines the amount of details an image can convey. It is usually measured as a Spatial Frequency Response (SFR), or so-called Modulation Transfer Function (MTF). For sharpness and MTF, we use the eSFR chart from Imatest in combination with Kino Flow controllable light sources also from Imatest

-

Dynamic Range is the range of exposure, i.e., scene brightness, over which a camera responds with good contrast and good signal-to-noise ratio (SNR). HDR (High Dynamic Range) is a feature present in most ISPs that allows the use of multiple images with different exposure times to be combined into a single high-quality image. For dynamic range measurements, we use an Imatest LED light box with a 36-patch transmissive chart.

-

The image gets darker from the center to the corner due to the radial nature of the lens. This non-uniformity can be mitigated by the SW algorithm Lens Shading Correction (LSC). For uniformity measurements we often use the CAL1 V2 integrating sphere from Image Engineering:

-

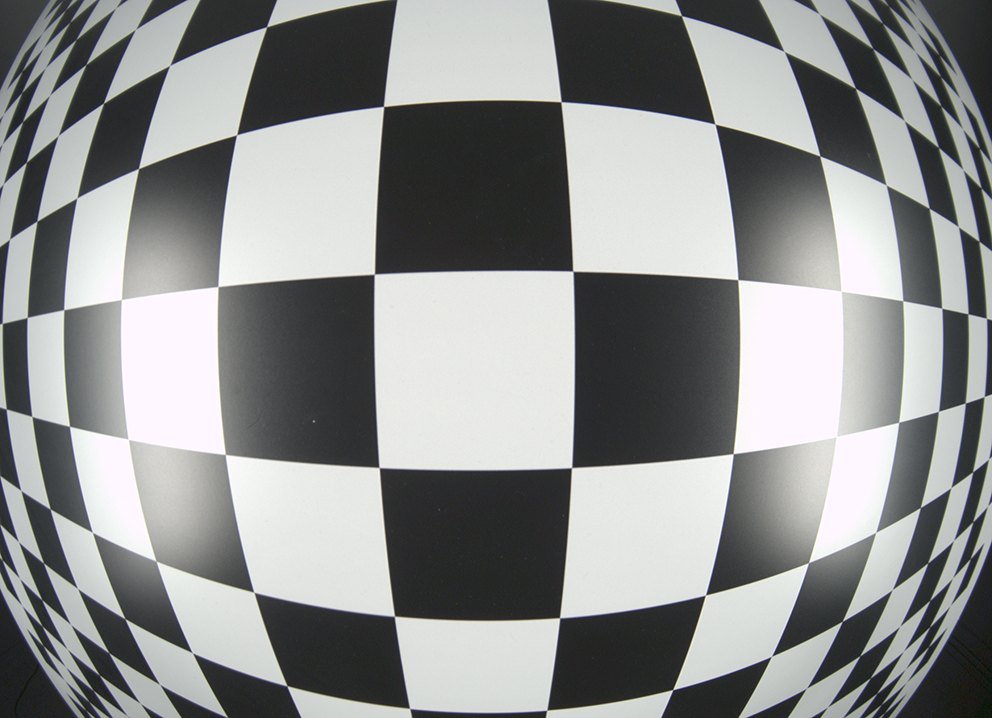

Distortion is an aberration that causes straight lines in the scene to appear curved in different parts of the image. Distortion is worst in wide-angle, telephoto, and zoom lenses. It is often worse for close-up images than for images at a distance. This can be improved with better optical components and/or software, and the performance needs to be verified in the lab using for example a dot target.

-

Color reproduction is an important objective factor that is a measure of how accurately the camera reproduces color from the captured object, but it is also highly subjective and dependent on the viewer’s perspective. We measure color rendering by obtaining images from a combination of industry-standard color charts (color checker, gray charts, etc.). We set up carefully calibrated custom lab scenes, and natural scenes under a variety of conditions. In the lab, a closed-loop system controls the lighting to ensure accurate light levels and color temperatures. The lighting conditions range from very low light to outdoor conditions. For color reproduction, we often use a still life and the Light Studio from Image Engineering with a color-checker chart

-

Flare, also known as veiling glare is stray light in lenses and optical systems caused by reflections between lens elements and the inside barrel of the lens. It predicts the severity of lens flare— image fogging (loss of shadow detail and color) as well as “ghost” images— that can occur in the presence of bright light sources in or near the field of view. (It does not measure the ghosts in detail.)

Veiling glare is measured by using a standard Kodak Q-13 or Q-14 step chart mounted beside a “black hole,” i.e., a box lined with black behind a small opening, mounted on a large whiteboard. For this test we have different options in the lab, for example, the ISO-18844 Flare test chart from Imatest mounted in an LED light panel.

-

The Noise attribute represents the amount of unwanted signal that appears in the overall camera experience. Noise comes from the light of the scene itself, but also from the sensor and the electronics of the camera. Depending on the origin of the noise there are different methods to quantify it. When the overall noise level is considered for an image that is to be presented to the human eye, our still life is an excellent way to subjectively improve until "perfection". In the case of electronic noise on the sensor it is quantified by signal to noise measurements from density patches "step chart" and by collecting dark images with different exposure time.

-

When a camera captures a frame, it requires a finite amount of time to collect the light, and if there are moving objects in the frame, they will inevitably appear smeared. Such smearing in camera image quality is commonly referred to as motion blur.

At Sigma we use dedicated hardware and software to objectively quantify motion blur. This is done by capturing an image of an SFR target, moving at a determined speed, and then analyzing the increase of the slanted edge rise time, using the SFR module in Imatest.

-

It is common that digital cameras read the image from the sensor line-by-line, causing fast-moving objects to be visibly distorted. Sometimes the knowledge of maximum object speed can be crucial for a chosen camera application. At Sigma we use the LED-panel from Image Engineering that allows us to measure and quantify the rolling shutter effects, emulating various object speeds.

Moreover, the LED panel can be used for precise timing of the video feed and for measurement of the frame rate of the video.

The Sigma Connectivity labs has many more tools and processes, and often we will also device and construct a custom made test based on a customers wishes and use cases.

Examples could be for non-visual cameras, such as near infrared cameras, far infrared (thermal) cameras or stereo/3D cameras. In those cases, many of the image quality processes are not applicable, but there are other tests and verifications that are important. If you have other requests do not hesitate to reach out to the optoelectronics team at Sigma Conenctivity, and see more about our labs here.

![Measuring - Imaging Lab [Social Media].jpg](https://images.squarespace-cdn.com/content/v1/61b8beb830183d717ffc4b02/ded99569-e2ff-4c6d-b887-2c22df233587/Measuring+-+Imaging+Lab+%5BSocial+Media%5D.jpg)

![HDR - Imaging Lab [Social Media].jpg](https://images.squarespace-cdn.com/content/v1/61b8beb830183d717ffc4b02/08a83c3a-bac7-4945-8276-6bb3b696b679/HDR+-+Imaging+Lab+%5BSocial+Media%5D.jpg)

![Controlled Light III - Imaging Lab [Social Media]_OPTO.jpg](https://images.squarespace-cdn.com/content/v1/61b8beb830183d717ffc4b02/a78c12a0-c859-4c4a-9b96-15ac97e31d98/Controlled+Light+III+-+Imaging+Lab+%5BSocial+Media%5D_OPTO.jpg)

CASE STUDY: Image quality tuning for a Qualcomm based body worn camera

A disruptive startup designed a body worn device including a camera that should be on par with high end mobile phones in all environments.

Sigma Connectivity provided:

In this case study, the camera tuning experts at Sigma provided the basic camera tuning,covering the optimization of exposure, white balance, noise reduction, and many more blocksnecessary for achieving good image quality. Relying on a comprehensive objective evaluation using standard test charts and light sources, the basic tuning ensured that the image produced by the pipeline was up to requirements. The tuning of a general-purpose camera does not usually end with basic tuning, and subjective tuning with regular feedback from the customer is needed. For this case study, Sigma completed an exhaustive set of field tests in various conditions to fine-tune the pipeline. As a result, Sigma has delivered a complete tuning of a wearable camera, surpassing the image quality of some smartphones equipped with similar hardware

Contact our team

Mattias Eriksson

Engineering Manager, Optoelectronics Design & Lab

CASE STUDY: Camera review and image quality tuning for a professional mobile phone

A customer developed a camera/handset for professional users and included an off-the-shelf camera module and found some issues and limitations when testing the first prototypes.

Sigma Connectivity provided:

Sigma Connectivity started by reviewing the selection of the camera module in relation to the use cases and did a first evaluation of the camera image quality. The objective was to determine if the integrated camera module would be able to meet the required use cases.

The second phase was to tune the image quality of the camera to actually meet those use case requirements