AUDIO AND ACOUSTIC LABS

Microphones, loudspeakers, audio DSP, and audio hardware codecs are examples of audio and acoustic components necessary to interact with a product. Whether you make a phone call, listen to music, give a voice command, or record a concert, at some point, you will come across something that has been developed in a lab like ours. Our Audio and Acoustic labs have everything necessary to design, develop, integrate, and optimize these components for your final product.

Whether we are testing advanced rapid prototypes of a key design element or tuning and verifying performance in an almost finished product, we will be using all the tools, systems, and rooms at our disposal to ensure that we deliver the highest quality and best possible outcome for your product.

Our Audio and Acoustic lab facilities are a part of our legacy from Ericsson and Sony Mobile and have been a central part of our offer since the foundation of Sigma Connectivity in 2013. We have consistently upgraded our capabilities to keep up with new test standards and technologies across a broad range of consumer products with audio and acoustic interfaces.

LAB EQUIPMENT

Sigma Connectivity’s world-class laboratory facilities and equipment provide an objective means for validating and tuning our Audio DSP offerings and designing and verifying hardware.

The quantity and diversity of our equipment enable us to confidently tackle a vast range of product types and project sizes. Regulatory standards can be met, and suitable test environments recreated.

Our equipment includes:

Two full anechoic rooms, one anechoic down to 200Hz with a daytime noise floor of 12dB(A) SPL.

Two further smaller anechoic measurement chambers.

Five reverberant measurement rooms are designed to measure ETSI ES 103 224 and 202 396 with loudspeaker arrays and variable reverberation times.

Five HEAD Acoustics labCORE ACQUA test stations.

A fully equipped Audio Precision APX525 test station.

Two Listen Soundcheck licenses and a dedicated test station.

Klippel Analyzer 3 system with laser measurement capability.

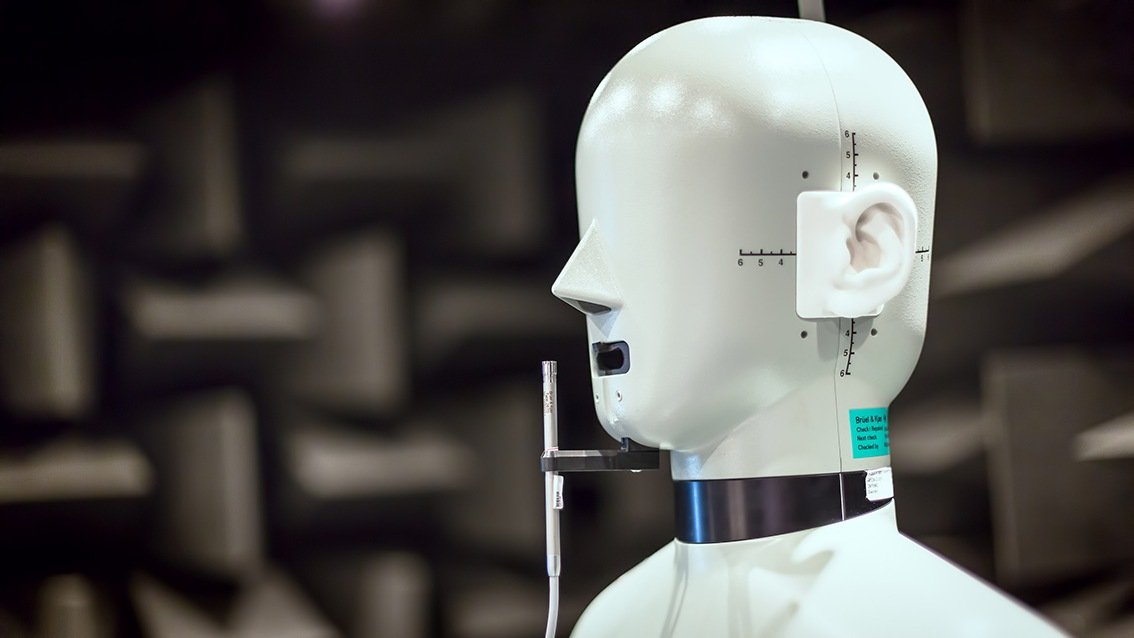

Nine Head and Torso Simulators (HATS), including two Brüel & Kjær 5128 high-frequency HATS.

Wind noise generator up to 20m/s for a HATS sized measurement area.

Two Rohde & Schwarz CMW500s for radio connectivity.

-

Our heritage is with mobile telephony. These days people speak via Teams, Zoom, social media, and gaming apps via the Internet. No matter how the speech is transported, we have expertise in all parts of the chain. How speech is generated by a human being, how it propagates from the talker’s mouth to the product, how it is affected by the product mechanics, its microphones, electronics, speech processing, speech coding, as well as the transport (which is subjected to packet loss and jitter) to the remote party where the data is recovered, decoded, processed, and played to some sort of loudspeaker or headphone. Further, how the sound couples from the speaker into the ear, and finally, how humans perceive speech (psychoacoustics). We also have insight into the conversation interaction aspects, such as how delay and transparency (double-talk performance) affect the overall conversational experience.

We have insight into the details of various parts of the chain, as well as how they affect the users' overall quality of experience (QoE). Our experts co-wrote some of the widely used communication acoustics standards. With our lab equipment, we routinely measure many parameters that pertain to the conversational quality. In some cases, we design and execute formal listening tests according to relevant industry practices and standards.

-

An audio capture system is comprised of many distinct parts, such as a microphone component, a mechanical acoustic port, meshes and membranes used for ingress protection, and audio ASICs that run audio DSP algorithms for noise and/or wind reduction. The development of such a system depends on many factors, such as the product's intended application and the types of environments it will be used in, both physically and acoustically. This process requires that these factors be considered, and then system hardware components are selected and integrated along with tuning and verification in our labs. The Sigma Connectivity audio and acoustic labs can support every stage of this process, from the initial testing of concepts to pre-certification against well-known standards for complete products.

We often start this process by constructing and verifying microphone port mockups using systems such as Audio Precision and Listen Soundcheck. When the microphone port concept is verified, we will integrate the solution into our product design and start performing verification for more advanced scenarios of audio quality using Head Acoustics Aqua and Listen Soundcheck.

Typical audio capture quality metrics we measure in our lab:

Frequency Response | Distortion | Microphone Sealing | Microphone Directivity | SNR | AOP | Quality in the presence of background noise (GMOS/SMOS/NMOS – mean opinion score predictions) | Perceptual objective listening quality prediction (POLQA)

-

The audio and acoustics team has extensive experience developing, testing, validating, and verifying voice recognition systems. Many voice recognition systems are used today in home appliances, electronic products, car systems, and many more. Testing involves gauging the performance of system wake words and commands in different conditions.

Wake word and command performance testing involves testing the True Detection Ratio (TDR), False Rejection Rate (FRR), Word Error Rate (WER), Wake word Delay Response (WDR), and much more. These tests are performed in a semi-reverberant room that complies with the ETSI standard and via Python script-based automation systems that involve the use of HATS and HEAD Acoustics Acqua.

-

Sigma Connectivity has extensive experience in product development, system integration, and testing of most loudspeaker technologies (micro speakers, IP-classified speakers, horns, large diaphragm speakers, and headphone receivers). Loudspeaker integration, especially into small products, can be complex. Space is often at a premium in a consumer product, and similarly, for microphone subsystems, we work very closely with our mechanical design engineers.

When starting a loudspeaker subsystem design, we often begin with Klippel Analyzer 3. KA3 is a measurement system that uses a laser measurement head that scans the speaker component while subjecting it to various stimuli. This enables the performance characteristics of the loudspeaker to be discovered and derive all the Thiele Small Parameters necessary for simulation and loudspeaker enclosure development.

To optimize the performance of a micro speaker in a consumer product, it is often necessary to use smart amplifiers capable of monitoring and controlling the speaker's voltage and current consumption to ensure that the speaker does not exceed its performance limits. This enhances and optimizes the speaker's performance so that it sounds better while protecting the speaker from damage and resulting in longer product life. Our expertise and labs provide the perfect combination to tune a smart amplifier system.

Using our test equipment (Listen Soundcheck, Audio Precision, Head Acoustics Acqua), we also regularly measure the following key performance characteristics of a playback system.

Typical audio playback quality metrics we measure in our lab:

Frequency Response | Directivity | Total Harmonic Distortion | Rub and Buzz | Output Level

-

We have the equipment to simulate many standardized background noise environments (pub noise, car noise, café noise, road noise, and train noise...), and we also perform wind-related measurements. Our wind generation equipment can provide air speeds up to 20m/s. Depending on the product, we have the capability of changing our setup according to the surface that is required. Data collection under such conditions can help to quantitatively and qualitatively measure the performance of noise cancellation algorithms related to outdoor conditions or find optimum position for the microphones used in a device.

-

Simulation is a way of trying out design solutions without making the actual physical prototype. A better initial design for the first prototype can be found, and the number of iterative design changes may be reduced, saving time and material.

Sometimes a system's mechanical and acoustical properties can be represented by a lumped parameter model, and we can predict its performance with an analogous electric circuit simulator, like Micro-Cap.

We can use COMSOL Multiphysics for more complicated geometries to do a more detailed simulation using FEM and BEM. COMSOL simulations model acoustic phenomena to improve applications such as speakers, microphones, rooms, etc. By studying the acoustic properties of an application through simulations, it is possible to optimize its performance before conducting lab tests. This cuts down on the time and cost of developing multiple prototypes.

-

We know how to optimize the electronic design for the highest demands. There are several aspects of signal handling in the analog domain, such as dynamic range, noise, signal integrity, hum, ground loops, etc. We also know how to make acoustic link budgets from analog acoustic domain, through analog electrical domain into the digital domain and vice versa. Choosing the right acoustic component for the acoustic task requires good knowledge of the analog system.

-

Audio signal processing allows us to develop algorithms that improve the audio quality of a variety of products based on our customers’ needs. This may include feedback cancellation in loudspeakers or hearing aids, adaptive filtering to eliminate unwanted noise in devices such as cameras and phones, beamforming algorithms, wind noise suppression, audio restoration, speech processing, sound effects, etc.

While developing audio signal processing, we continuously verify our implementation using our lab equipment to ensure we are on the right track.

Please follow this link to read a detailed description of our audio DSP offering.

Contact our team

Mattias Eriksson

Engineering Manager, Optoelectronics & Audio Design